Table of Contents

- Why Do Lean Construction Workflows Matter?

- PDCA Cycles in Construction Projects

- Setting Up Lean Construction Workflows

- Using Imerso and Solibri for Lean Construction Excellence

- Secret Feature That Closes the Cycle

- Conclusion

Why Do Lean Construction Workflows Matter?

Traditional design-bid-build or design-build construction project delivery methods tend to separate the different parties, creating silos and hindering collaboration. This makes teams focus solely on their own tasks, missing out on the bigger project picture.

Often when issues arise, it’s already too late, the blame game begins, and no one takes the initiative to find real solutions. Not exactly inspiring, right? But fear not, because lean construction workflows are here to save the day. They are usually based on the Integrated Project Delivery approach.

PDCA Cycles in Construction Projects

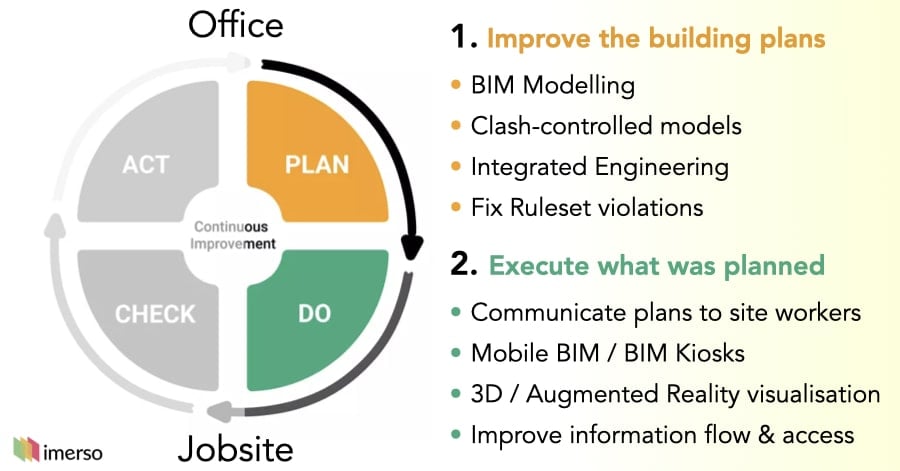

Plan-Do-Check-Act (PDCA) is a systematic and iterative management method used to achieve continuous improvement in various industries, including construction.

PDCA follows a four-step cycle:

- Plan - outline what you need to do.

- Do - execute your plan.

- Check - measure the results and analyse the variance from the plan.

- Act - take action. Make a decision whether to continue on the same path or make a change.

This cycle can be of any time length, but the shorter it is, the faster your feedback loop will be. This leads to better learning opportunities and a tighter control on the health of your project. PDCA promotes learning from experience and making data-driven decisions to improve processes and outcomes.

This cycle can be of any time length, but the shorter it is, the faster your feedback loop will be. This leads to better learning opportunities and a tighter control on the health of your project. PDCA promotes learning from experience and making data-driven decisions to improve processes and outcomes.

Key features of PDCA:

- Four-step iterative cycle: Plan, Do, Check, Act.

- Focus on continuous improvement and learning.

- Data-driven decision-making based on evaluation and analysis.

- Iterative implementation of changes or improvements.

- Emphasis on problem-solving and process optimisation.

Lean construction workflows generate immense value for everyone involved. By breaking down barriers and fostering teamwork, they deliver exceptional results. Stakeholders rejoice, as projects are executed with greater efficiency, improved quality, and enhanced satisfaction. It's a win-win situation for everyone.

Setting Up Lean Construction Workflows

Setting up Lean construction workflows means establishing a continuous, dependable, and predictable process with a strong focus on open communication. You should only move to the next stage of the cycle once the previous one is completed.

When communication is disrupted, it leads to wastage. For instance, if one team falls behind schedule and fails to communicate, the next crew may arrive too early to carry out the next phase of the project.

There are plenty of great construction tools on the market. When analysing your current processes, ask yourself:

- Do we have an outlined process for PDCA?

- Do we leverage digital software to make the process simultaneous and smooth for everyone?

- Are we able to execute PDCA in one single continuous workflow?

- Do our teams have an open and clear communication routine?

- Do all our teams have access to the right data and reports?

- How can we improve existing processes?

You can run a SWOT analysis to identify strengths and weaknesses, opportunities and threats of your current PDCA.

From our experience, it’s the C (Check) that often ends up among the weakest.

The reason for this is that the onsite reality changes so rapidly, that it seems impossible to analyse the variance from the planned model specifications. As a result, the lack of accurate and up-to-date As Built information becomes a serious handicap for fully relying on BIM models for project management.

Let's explore how you can overcome this challenge by implementing Lean workflows with new technologies like Imerso and Solibri.

But before we jump in, let’s align on what these tools are for.

Using Imerso and Solibri for Lean Construction Excellence

Solibri For Lean Construction Planning

If you’ve never heard of Solibri, you’re frankly behind the curve in the BIM game. But no worries, we’re here to catch you up!

Solibri is a software tool widely used in the design and construction phases with Building Information Modelling (BIM) projects, but has practically become the go-to solution for construction projects of all types and sizes.

The primary function of Solibri is to analyse BIM models and provide logic-based rules to determine potential issues, including typical clash detection and quality assurance analysis. It’s particularly useful for those involved in complex building projects, where there is a lot of information to manage and coordinate.

When you have different teams responsible for creating and delivering BIM models specific to their disciplines (eg. MEP, HVAC, Superstructure, etc), it’s vital that all are well coordinated and that this verification is done and iterated upon right from the start.

Imerso For Lean Construction Check

If you never heard of Imerso either, you may have a better excuse here, given how recently this software came out.

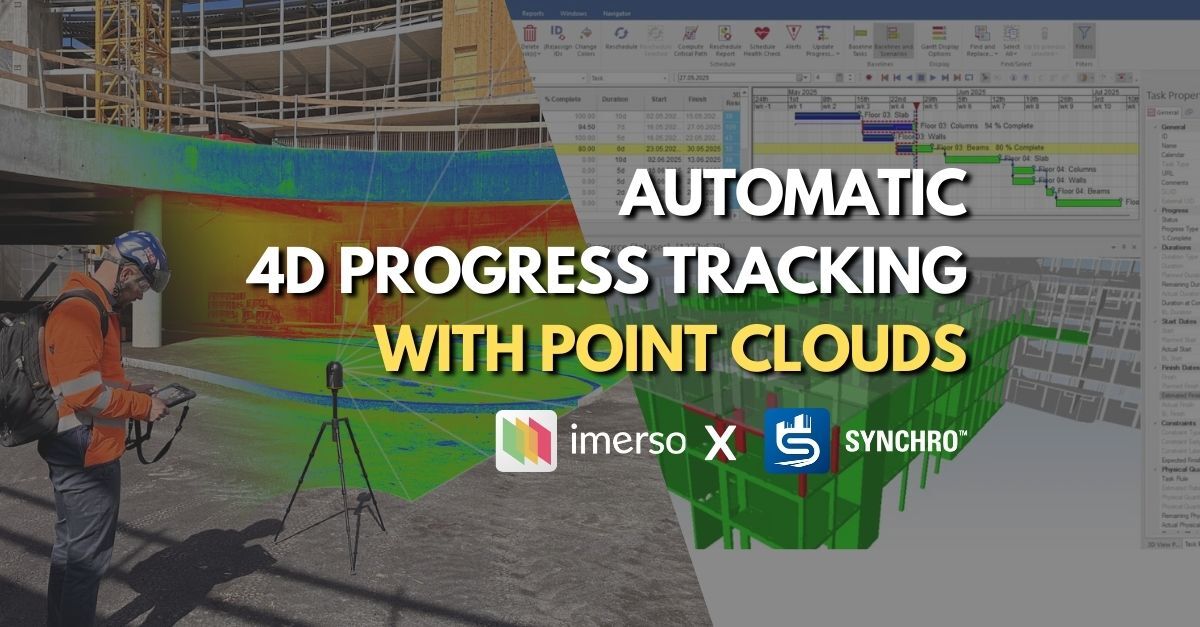

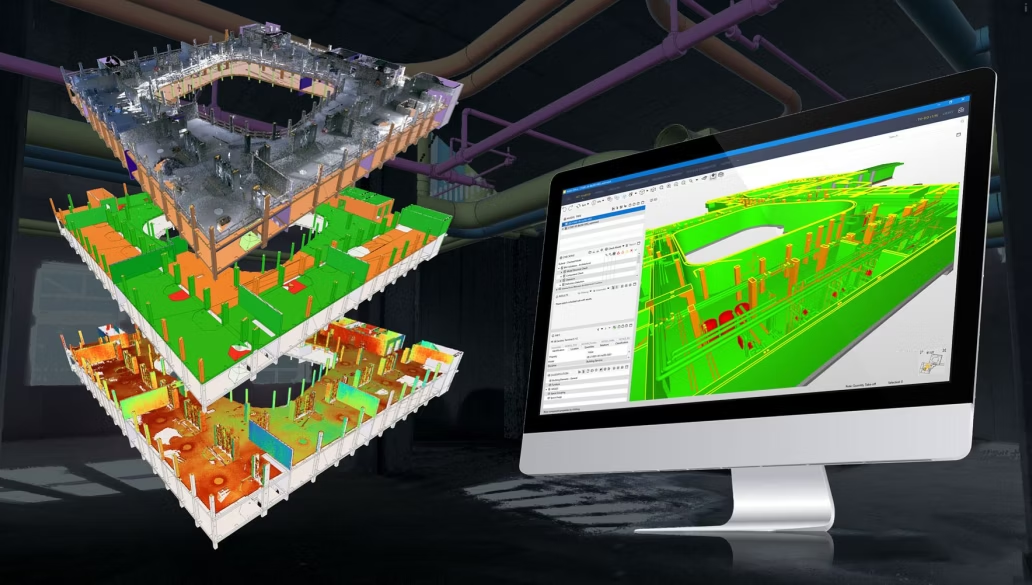

Imerso is a software platform that solves the challenge of tracking the As Built status routinely with more accuracy and less resources than manual and visual control methods, while also leveraging AI to validate the latest onsite conditions against the BIM specifications automatically.

Imerso’s customers span 13 countries and include renowned construction companies like Vinci, AF Gruppen, Betonmast, Drees & Sommer, NCC and frankly, we’re very proud of the results:

Secret Feature That Closes the Cycle

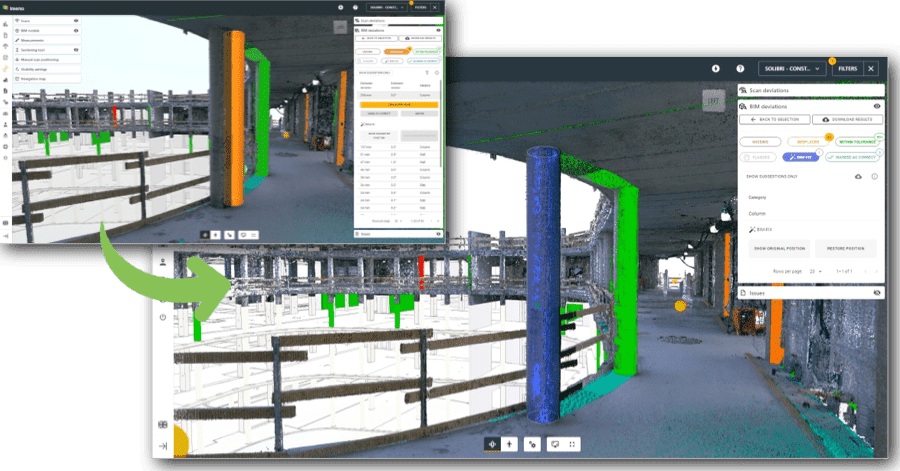

One of the most popular capabilities among Imerso users is the ability to update BIM models to their correct reality onsite. Imerso allows exporting As Built BIM models into Solibri in minutes without the need for extensive manual model updates of hundreds of deviated objects that require no onsite rework.

Imerso’s BIM-Fix function automatically moves your BIM objects to their real As Built location

Imerso’s BIM-Fix function automatically moves your BIM objects to their real As Built location

For a deeper dive into the use cases and functionalities of the Imerso - Solibri combination, check out the article titled "Unlocking Powerful Lean Construction Workflows with Solibri - Imerso Combo".

Conclusion

Mastering Lean construction workflows requires the integration of key methodologies such as IPD contracts and PDCA cycles, together with technologies like Imerso and Solibri.

IPD and PDCA bring a collaborative and continuous improvement mindset to construction projects, enabling teams to optimise efficiency, quality, and overall project success.

With technology like Imerso and Solibri the theory turns into practice. Real-time access to detailed As Built data, combined with the ability to analyse and validate BIM models, enables teams to make informed decisions, reduce rework, and improve overall project performance.

By embracing collaboration, continuous improvement, and leveraging the power of technology, you navigate complex projects with confidence, deliver superior results, and transform the industry towards a more sustainable and innovative future.

About Imerso

Imerso is a software platform that combines BIM, Reality Capture, and AI technologies to automate construction site supervision and quality inspections with one simple workflow. We help construction companies cut project risks and delay costs with real-time monitoring of site status and work quality. Here are 7 Powerful Ways of Using Imerso to Supercharge Your Construction Projects.

.png?width=350&height=147&name=Imerso_Logo_A4_White_Transp%201%20(1).png)

.jpg)