Status tracking on autopilot

Imerso checks work status, tracks progress, verifies quality of completed works, spots hidden errors, predicts upcoming clashes — and much more.

Launch in less than 3 Days

Easy to learn in minutes — No specialised experience with BIM or laser scanning needed.

Grow Site Performance

Capture accurate As-Built 15x faster, and keep everyone on the same page.

Connect your CDE and other tools

Share collaborative data to accelerate onsite and offsite workflows.

Close the gap between the plans and reality

How it works

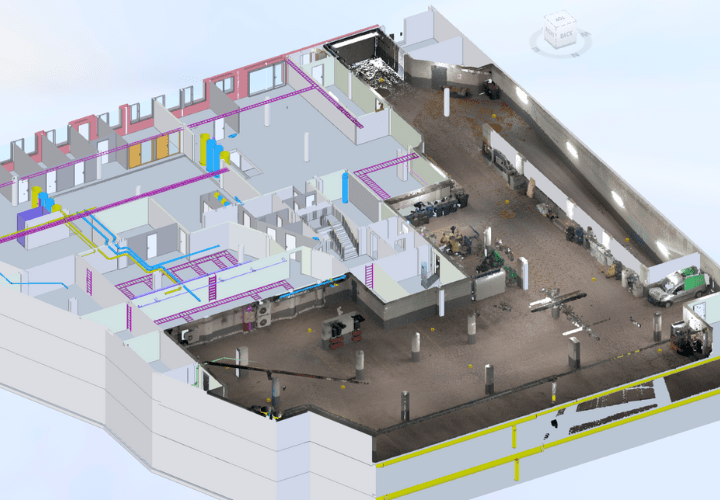

Step 1: Sync your BIM files

Turn your BIM models into measurable metrics to track performance across the construction phase.

Let's get started.

Step 2: Capture the site

Scans the site as simply as taking pictures with the easiest and fastest scanning workflow ever.

Capture As-built effortlessly on every visit, whether you're a laser scanning pro or first time user.

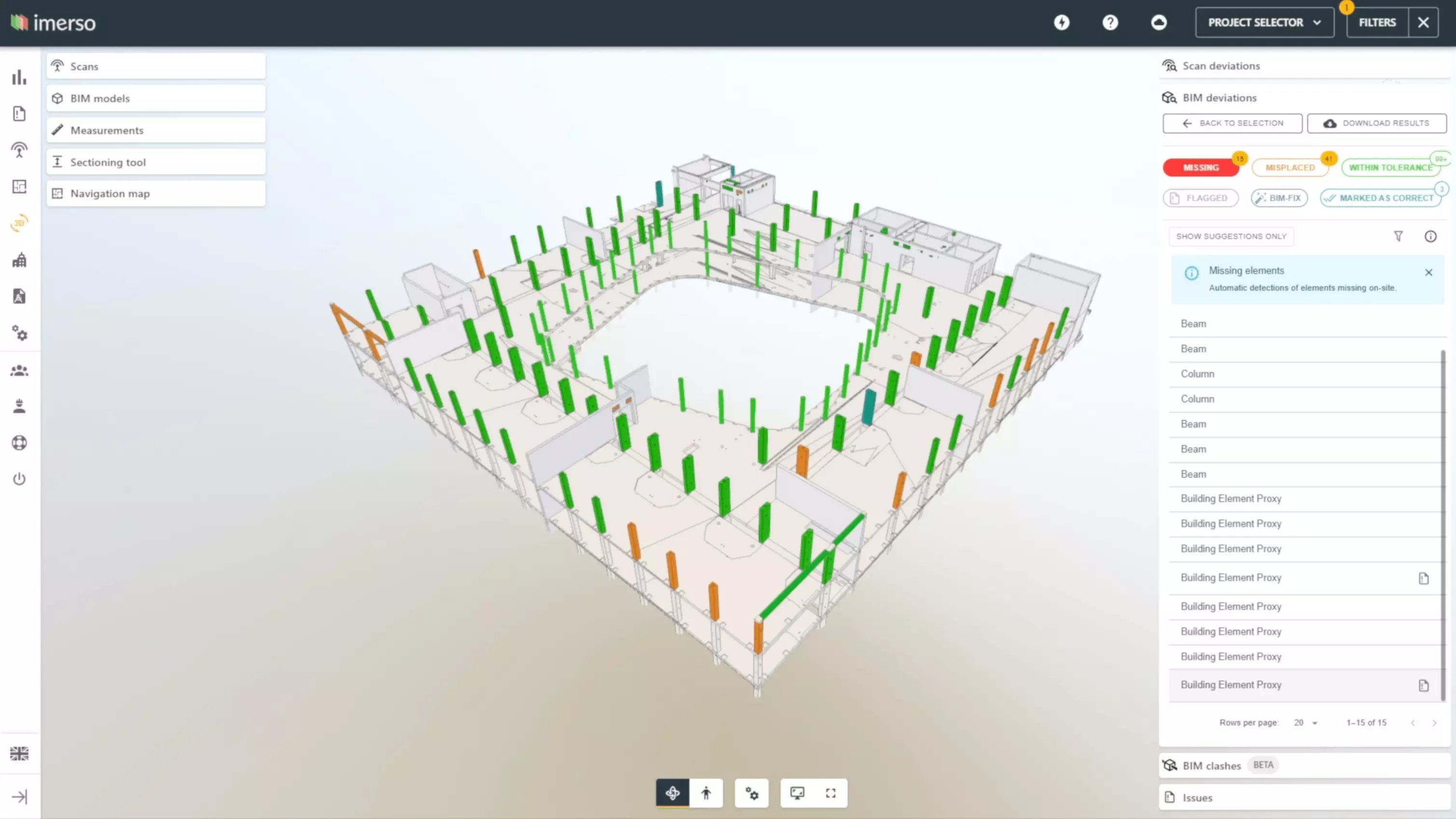

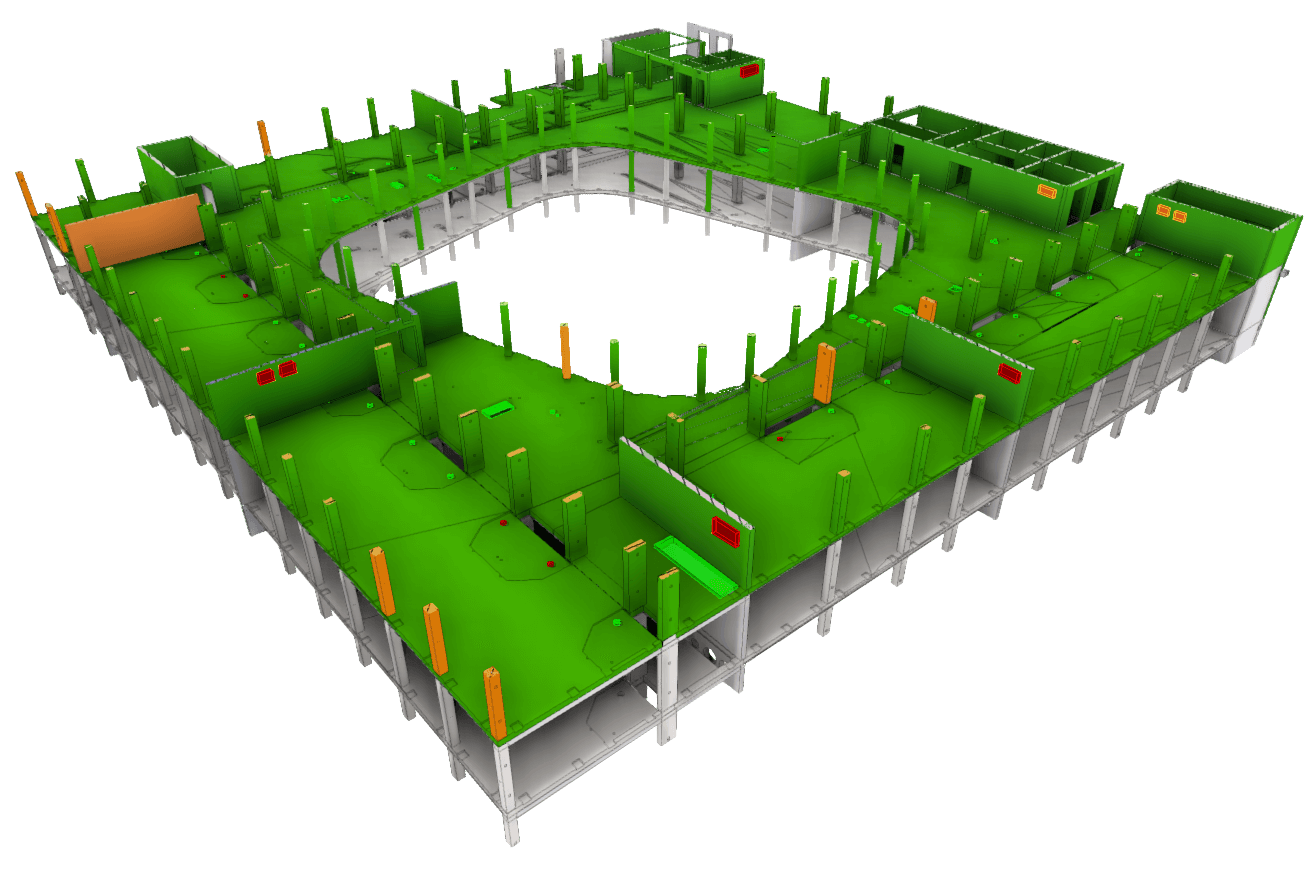

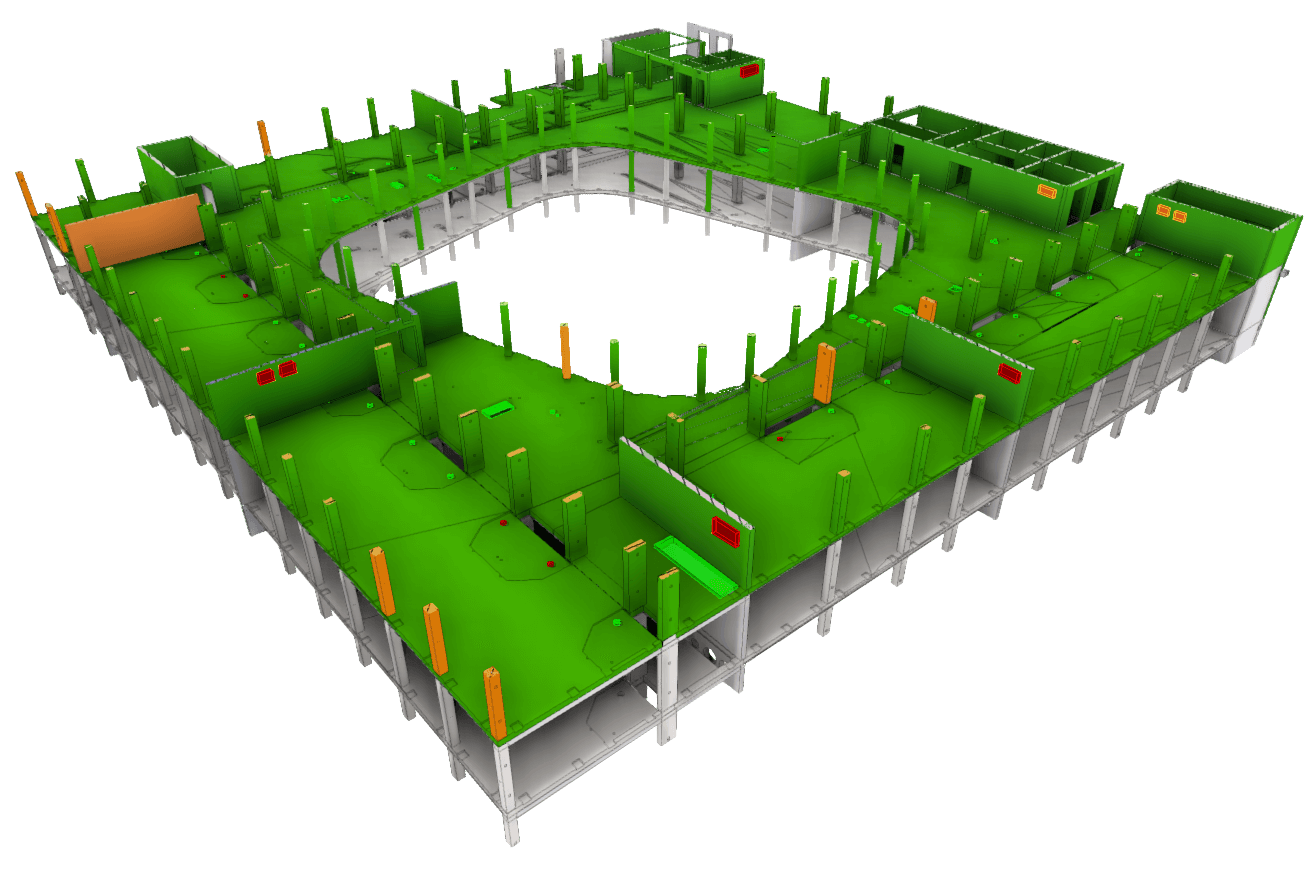

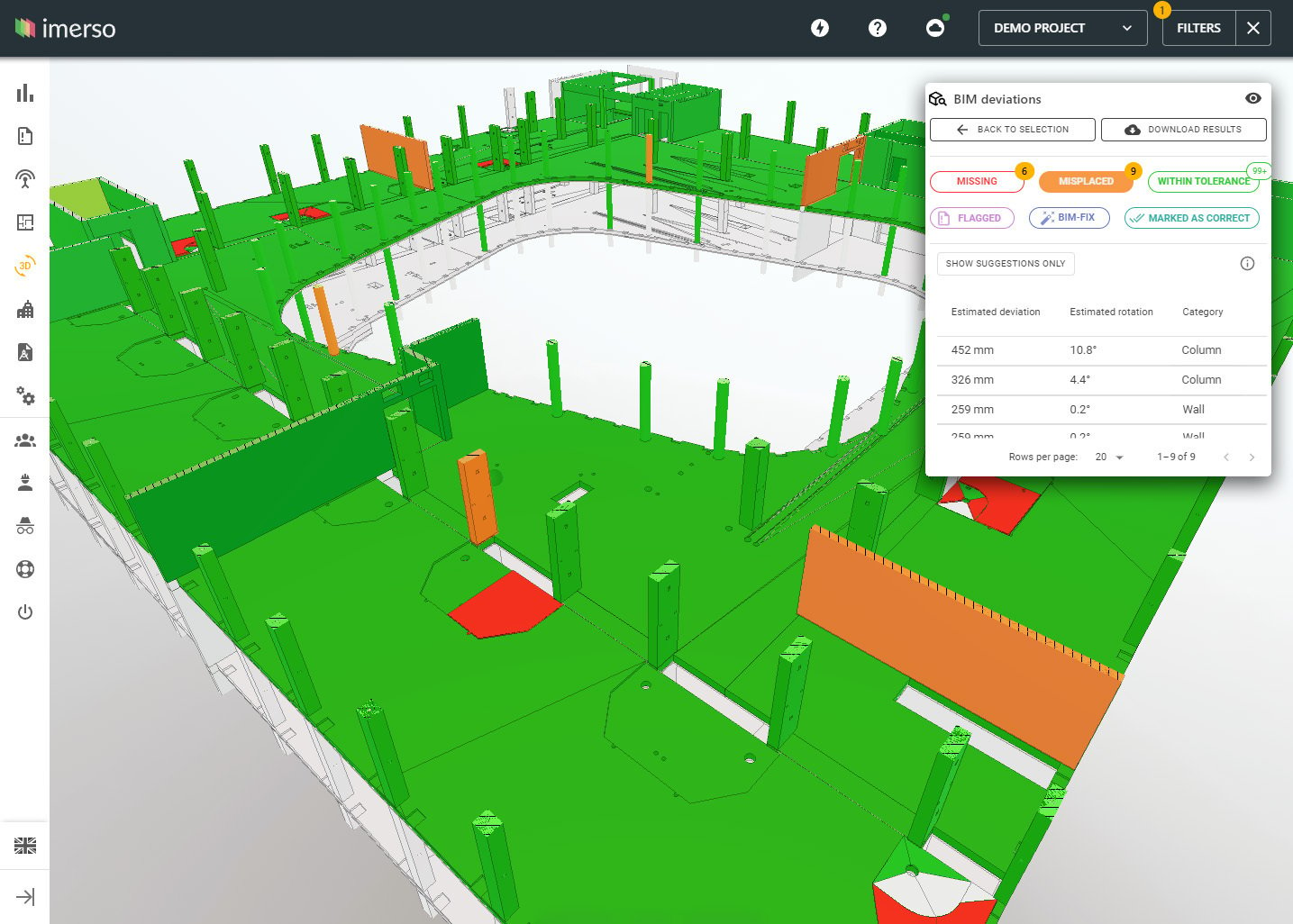

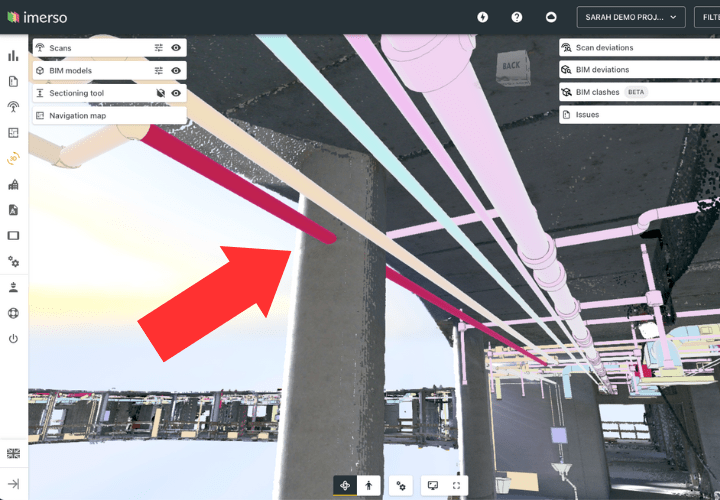

Step 3: Check the results

- Status of completed works

- Missing objects

- Out-of-tolerance installations

- Upcoming clash alerts

- Progress & Completion

- Quantity Take-Offs

- And much more...

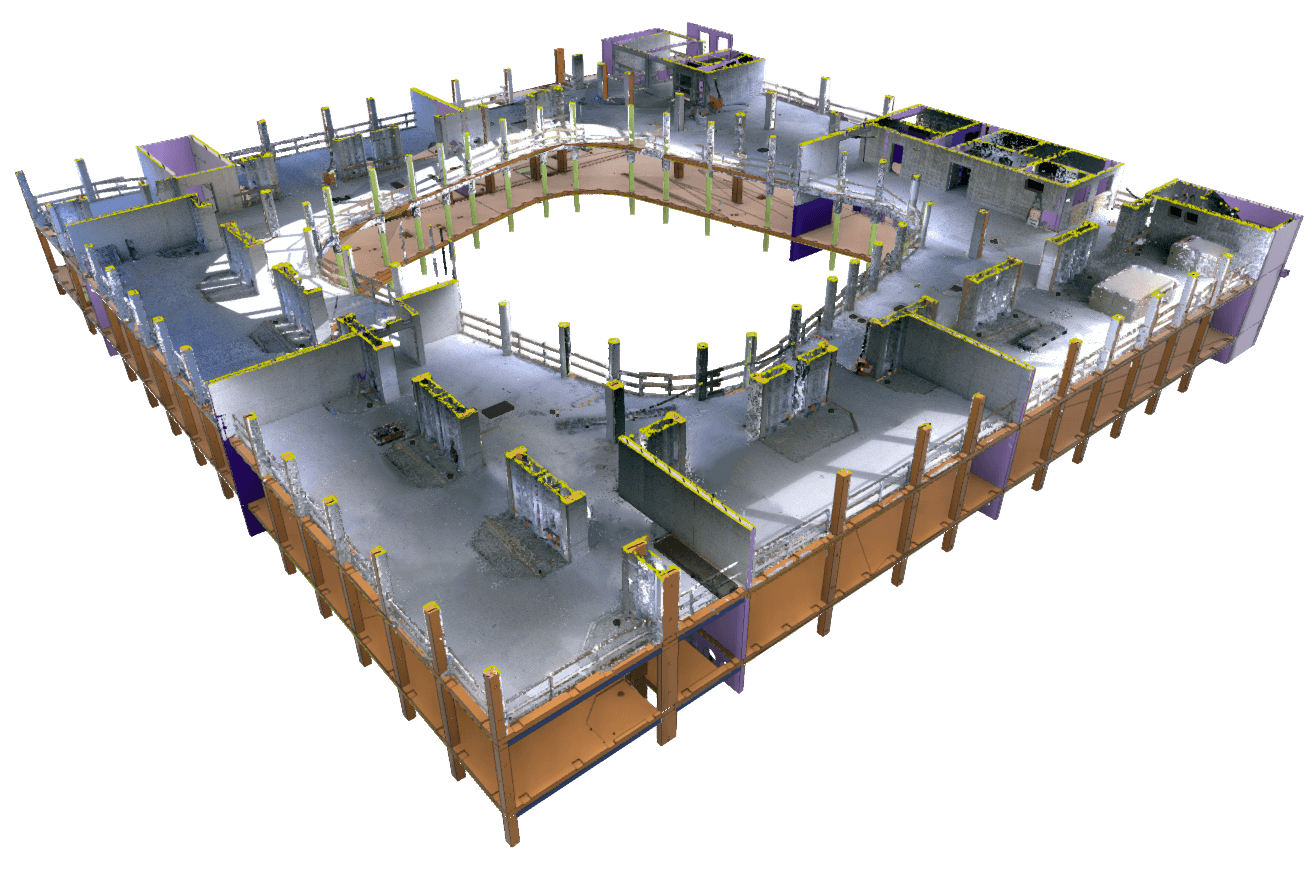

Step 4: Share and dive deeper

Tag the responsible teams and give them

unprecedented contextual data to reduce change orders and accelerate issue solving speed by 2x.

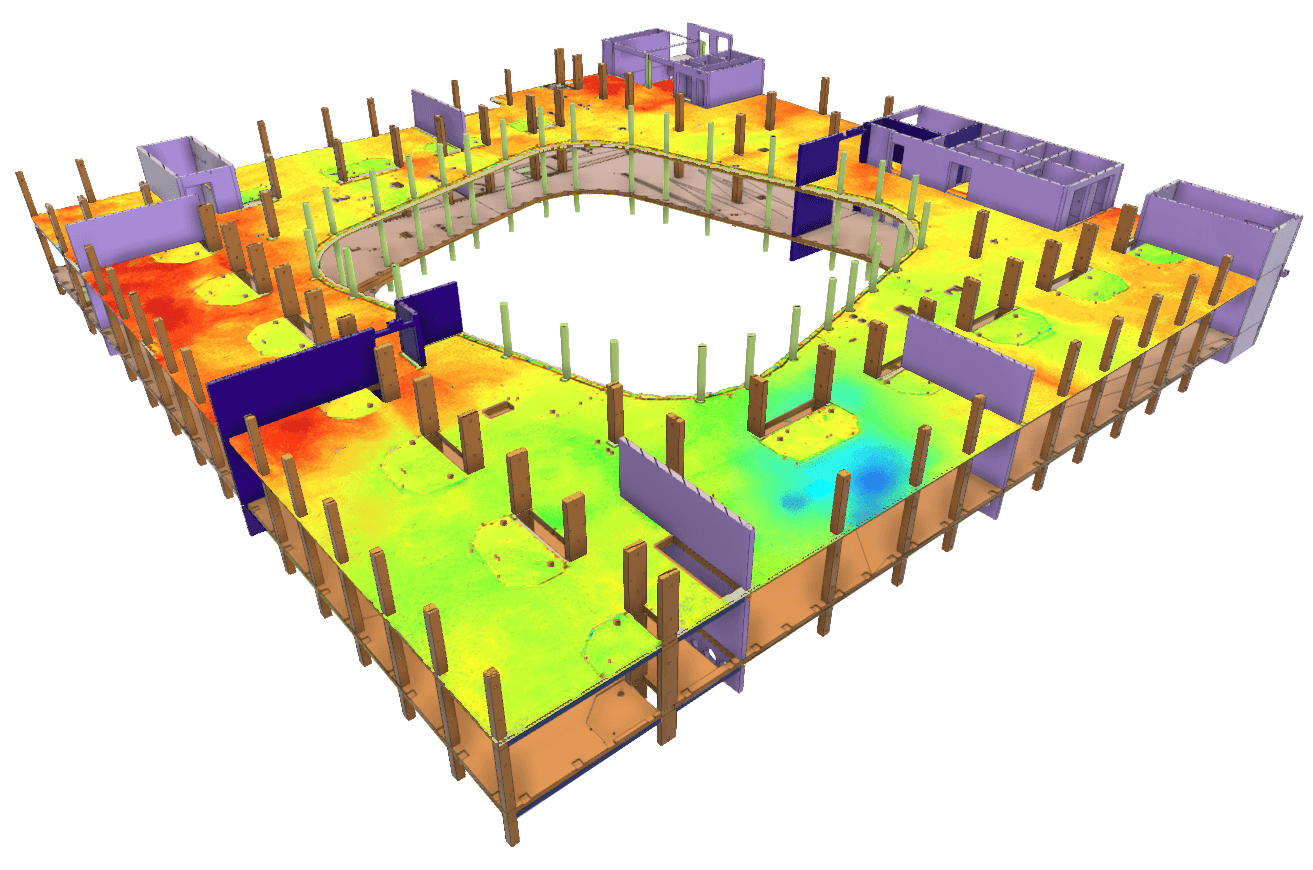

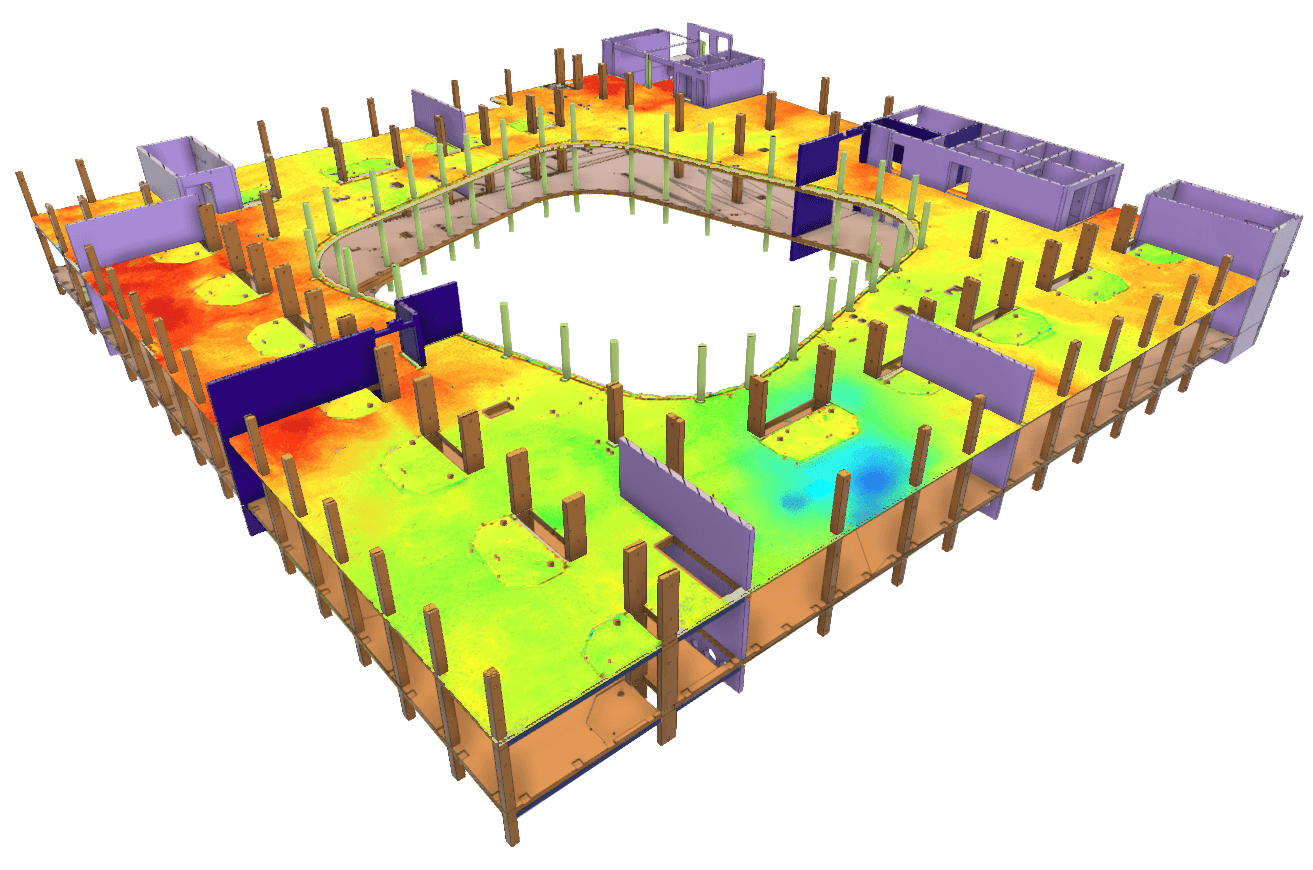

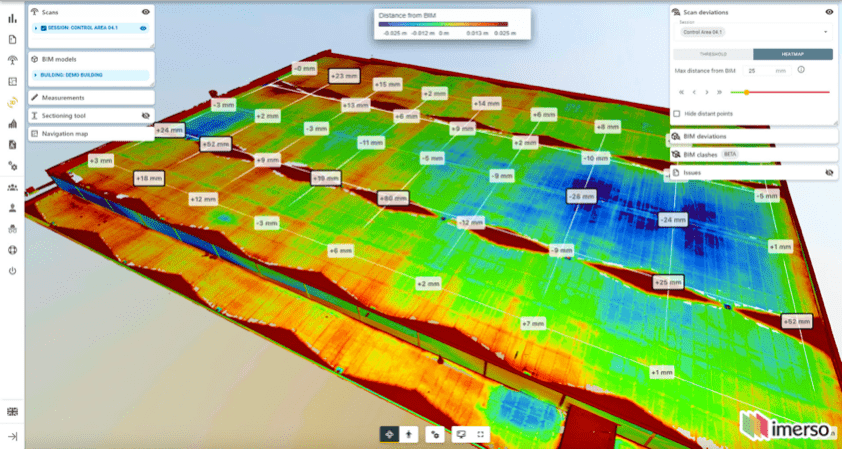

Surface and Level analysis? Done!

Share issues in a simple floor-plan? You bet.

Integration with popular software? Hell yeah.

Auto update BIM to As-built? 🤯 Whaaat..?

Stop chasing others for site info

Take control of your projects today.

How it works

Step 1: Sync your BIM files

Turn your BIM models into measurable metrics to track performance across the construction phase.

Let's get started.

Step 2: Capture the site

Scans the site as simply as taking pictures with the easiest and fastest scanning workflow ever.

Capture As-built effortlessly on every visit, whether you're a laser scanning pro or first time user.

Step 3: Check the results

- Status of completed works

- Missing objects

- Out-of-tolerance installations

- Upcoming clash alerts

- Progress & Completion

- Quantity Take-Offs

- And much more...

Step 4: Share and dive deeper

Tag the responsible teams and give them

unprecedented contextual data to reduce change orders and accelerate issue solving speed by 2x.

Surface and Level analysis? Done!

Share issues in a simple floor-plan? You bet.

Integration with popular software? Hell yeah.

Auto update BIM to As-built? 🤯 Whaaat..?

Stop chasing others for site info

Take control of your projects today.

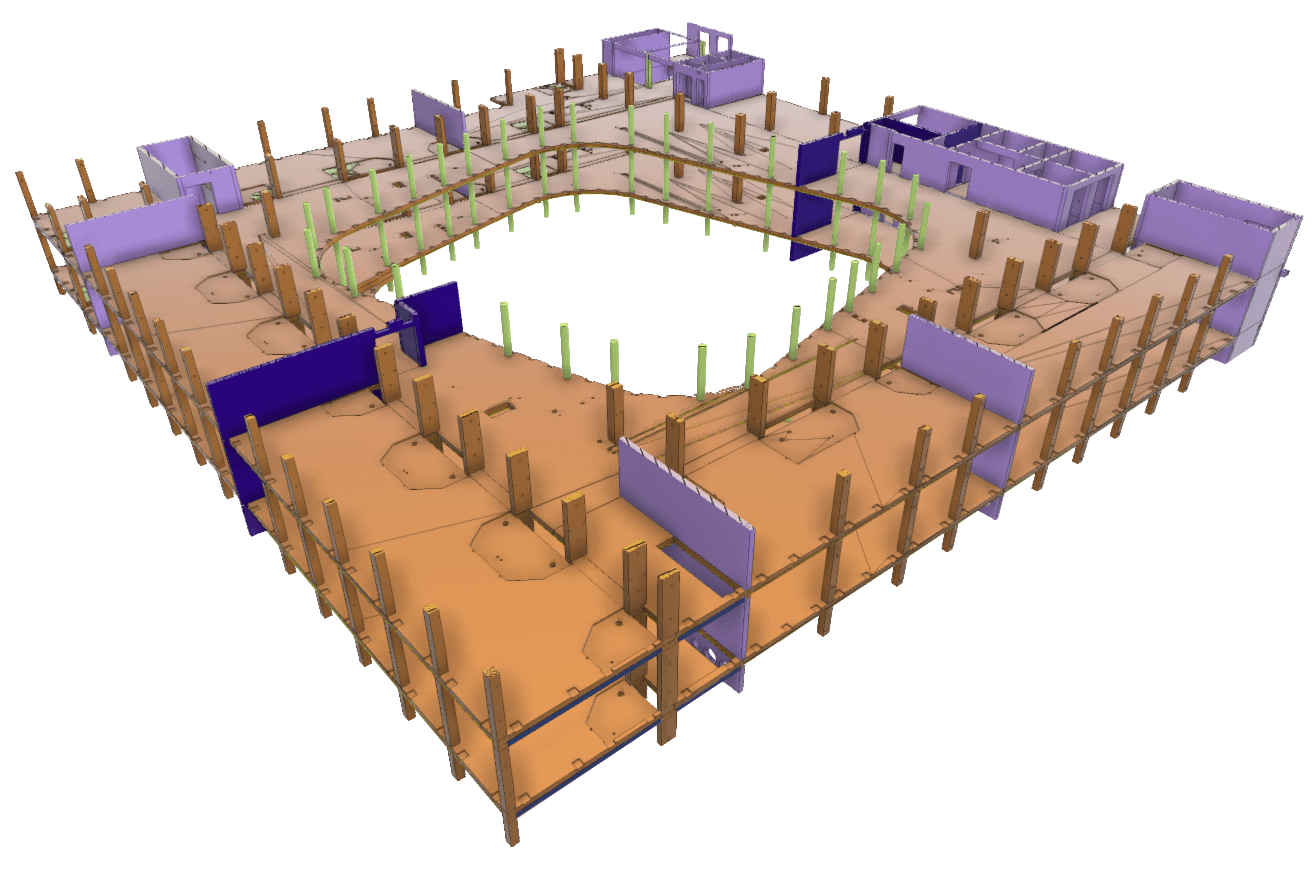

Imerso coordinates BIM with the field

All the site data you need, without the travels

Get your site teams and remote partners instantly on the same page about what's going on, with unprecedented contextual insight.

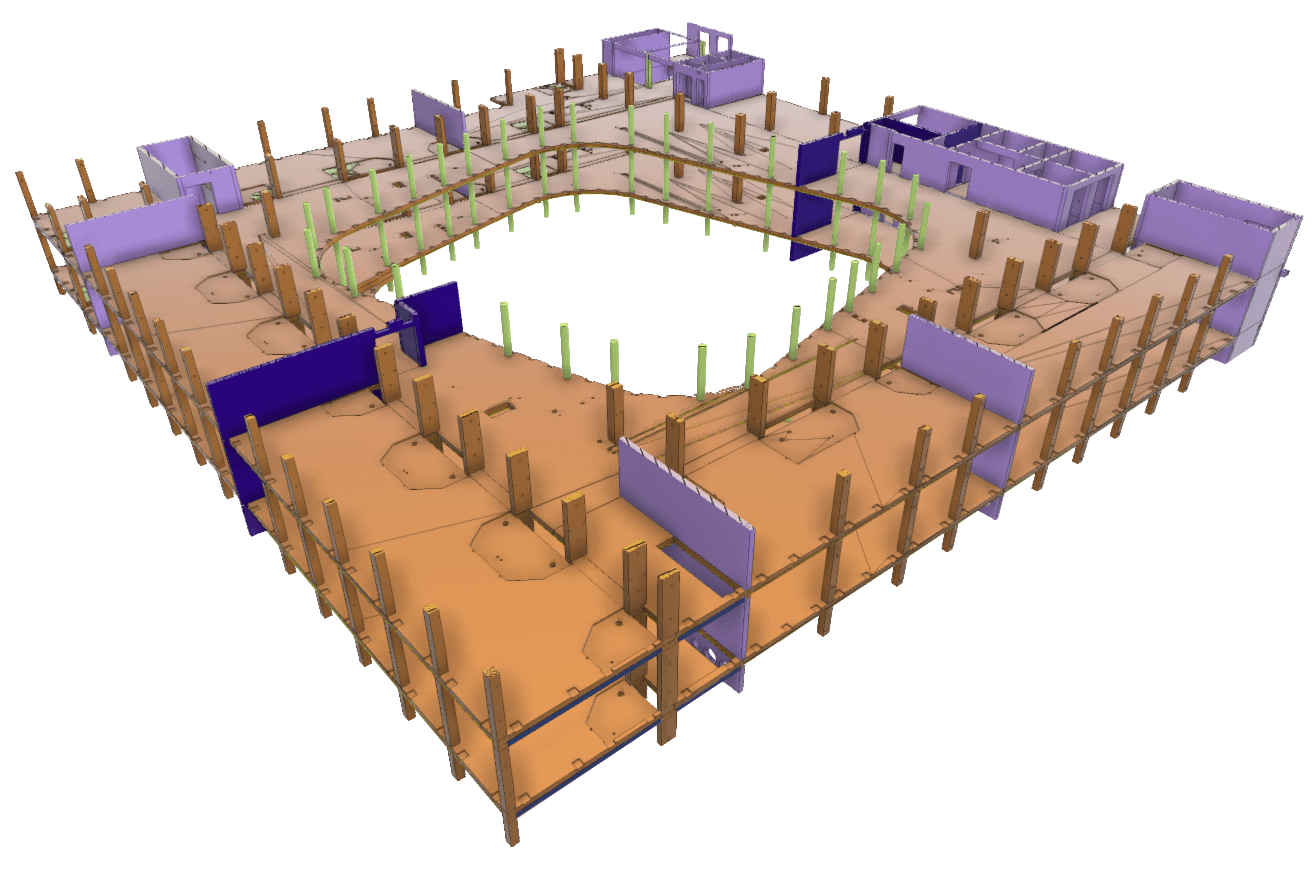

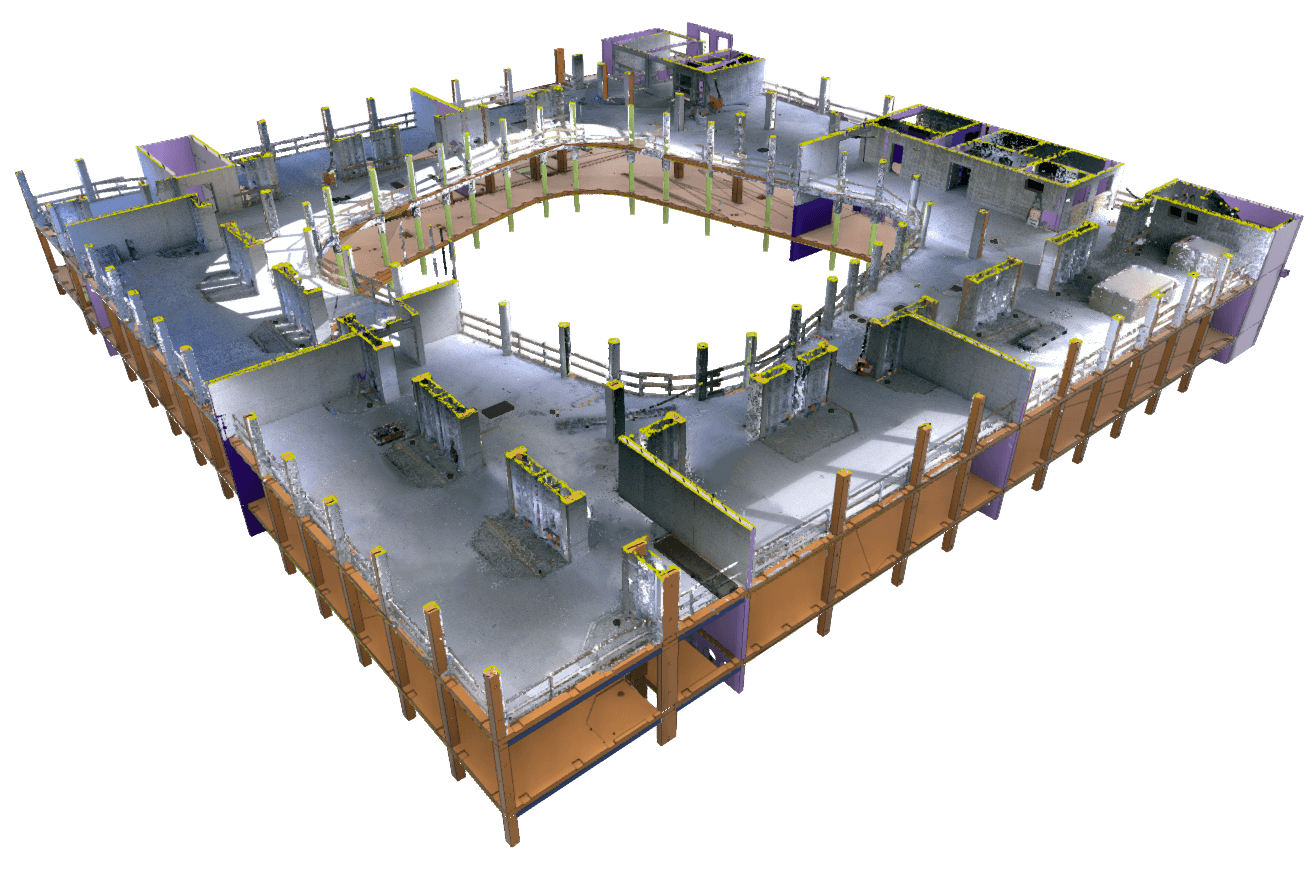

Verify completed works and site status

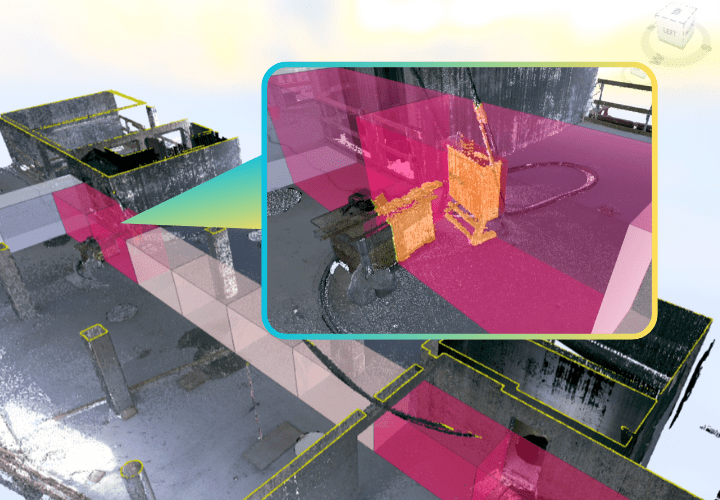

Predict future clashes before they happen

Check if the models for planned upcoming work still fit the current onsite reality. Get early alerts of upcoming clashes and solve problems before they happen.

Update BIM objects to their real onsite place

Detect obstructed HSE escape routes

Ensure that materials and equipment laying around at the site are properly stored away, and are not obstructing the designated escape routes.

Surface analysis and elevation grids

Check floor, ceiling, and wall slabs for elevations or depressions outside tolerance in minutes, without need for costly specialised resources.

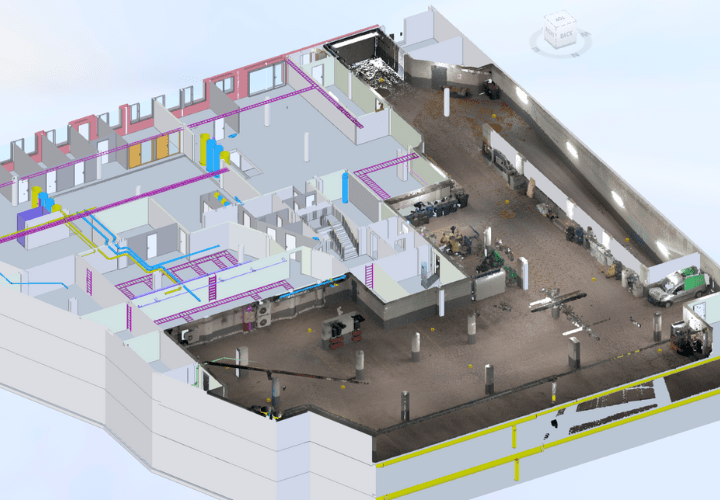

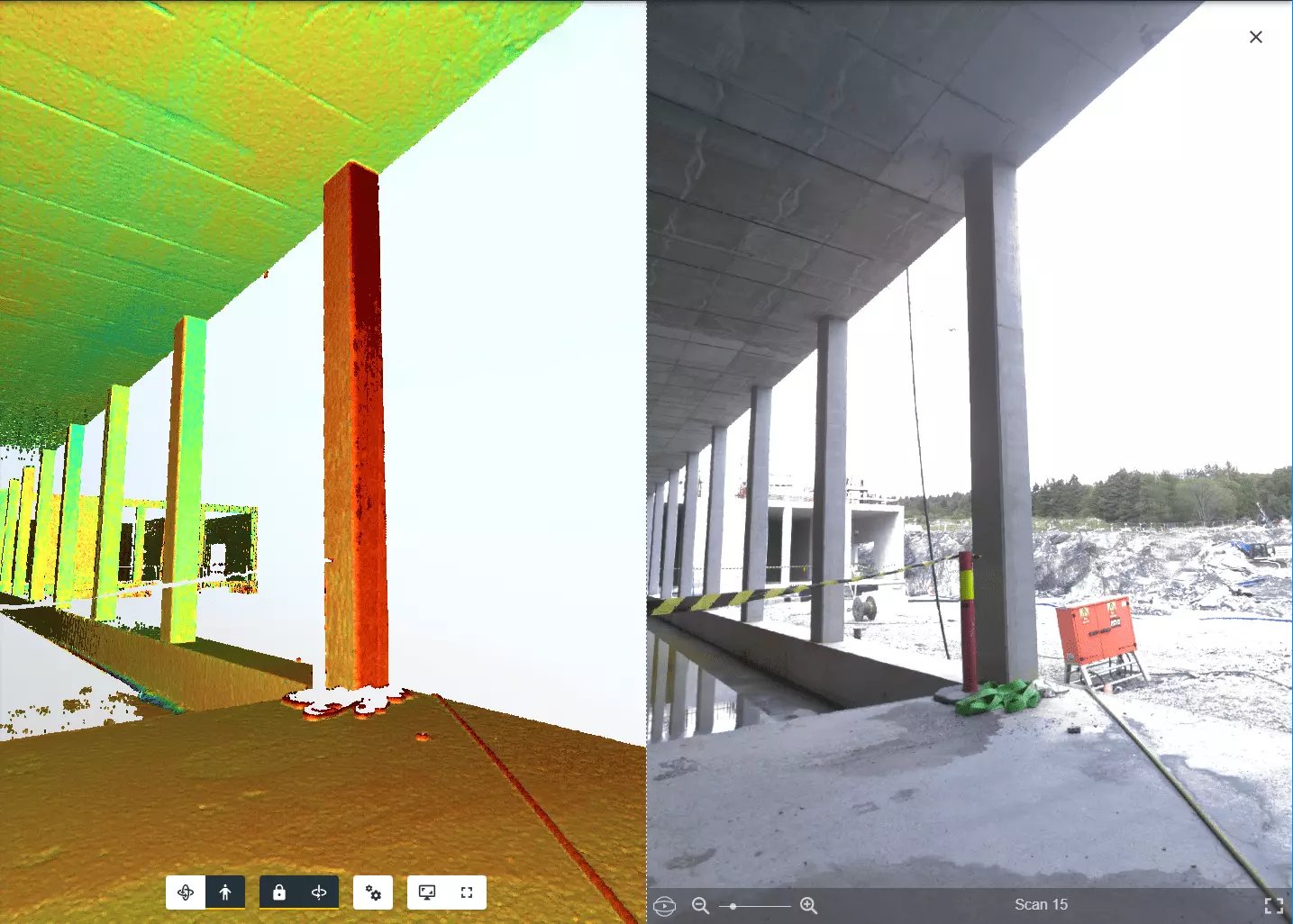

3D Scans and 360° Photos, side-by-side

Imerso lets you see what other overlook when looking at BIM and images alone. Get full context of the onsite reality, augmented by precise 3D analytics.

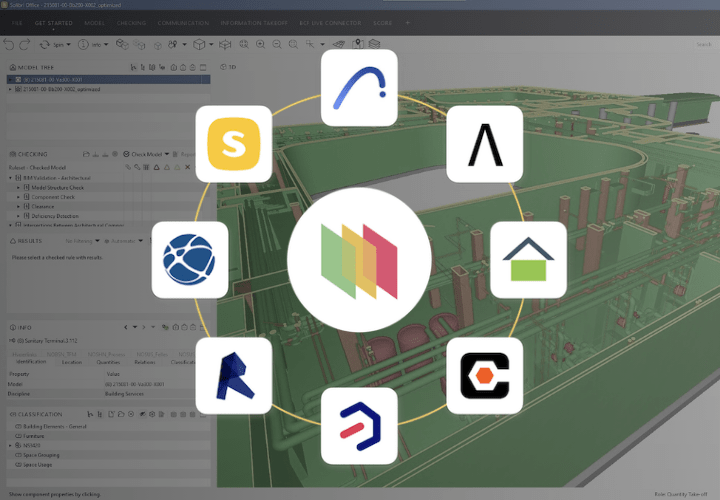

Powerful integrations and data sharing

API Integration and open data exports to use your data with Bentley Synchro, CatendaHUB, Autodesk Cloud, Procore, Revit, Solibri, Allplan, ArchiCAD, Dalux, and more.

Launch in just 3 days

Get Imerso deployed live at your worksites in under 3 days from our intro call.

Any of us can go scan the site in the morning, and have a full analysis ready for our team to review after lunch.

This was not possible before.

It really improved how we approach quality and interface issues.

NHN boosts productivity worth 2% of its hospital construction budget

The Nyt Hospital Nordsjælland (NHN) is an ongoing hospital construction project in Denmark. With Imerso, the team cut construction claims for work errors, implemented faster and better site supervision and more efficient process for As Built documentation.

-2.png?width=1010&height=568&name=unnamed%20(1)-2.png)

Imerso prevents dozens of fire-safety compliance issues at €1 Billion project

Byggstyrning streamlines prefabricated construction with automated inspections

The project management firm Byggstyrning captured the onsite status of this 23.000 m2 project on a weekly basis for instant inspection in Imerso. This allowed to resolve any problematic areas proactively and ensure a frictionless fit of prefabricated elements.

Frequently asked questions

What types of 3D / Laser scanners can I use with Imerso?

Imerso supports all scanners in the market, including devices from Navvis, Leica Geosystems, Faro, Trimble, Zoller, etc.

For a seamless experience, from site scanning to inspection results, we recommend the BLK360 devices (both 1st and 2nd generations) from Leica Geosystems, which are fully integrated with Imerso.

You can use both stationary scanners (tripod) and mobile (SLAM) devices — whichever feels most comfortable.

There are pros and cons to each of these solutions. We're happy to advise you on the best choice for your company.

Drop us a line and we'll share our best practices.

How does Imerso determine what is outside tolerance?

Users define the tolerance parameters they want to use, and Imerso applies those values to the inspection tools.

You can set custom tolerances levels for different element types (eg. structural objects, HVAC, or MEP objects) in your Imerso inspections.

Imerso also allows users to modify the tolerance value during the inspection, and the results will update automatically.

We work with tight tolerances. Do we need the highest accuracy scanner?

No — You don't need the highest accuracy 3D / laser scanner to use Imerso.

Most of our customers typically run routine construction inspections with tolerances ranging 10-25mm — depending on the object classes they're checking.

New generation devices like the BLK360 scanners from Leica Geosystems (1st and 2nd versions) deliver scan data with 5mm accuracy. These are quite affordable devices and extremely effective and fast to cover 99% of your construction quality verification needs.

Be aware that higher accuracies and capture ranges in scanning hardware come at a cost. Not just of a higher price, but also of a slower and less agile scanning process onsite. This will hamper your teams' ability to do this as a frequent routine.

From our experience, you'll get much more value from prioritising scanning frequency and agility. So that your teams could easily do it throughout the project. Instead of doing it once or twice with top-of-the-line equipment that only 3rd party experts can handle.

My scanner accuracy specs show "+- 5mm". What does this mean?

You aren't alone here. The misuse of the terms "accuracy" and "precision" is a constant battle in the surveying community.

For simplicity, you can read that number as the level of "Noise" in the captured scans.

If you capture a wall in your scan, the 5 mm accuracy value of your scanner doesn't mean that the wall object itself is misplaced by that value. Rather, it means that each of the millions of individual point representing that wall may be misplaced from reality by +- 5mm. The lower the accuracy, the more "noisy" the resulting scan.

As a result, capturing larger objects such as structural walls and large HVAC elements is less impacted by this variance. Conversely, capturing small objects like electrical cables and rebar will be more challenging with lower-accuracy devices.

Can I only use Imerso in the cloud?

We've built Imerso as a cloud-based platform. This allows our customers to leverage infinite on-demand scaling of servers and computation speed, without investing in expensive local server systems and powerful computers.

This also allows our team to constantly push new feature releases and software updates to keep all Imerso customers on the newest version.

For customers needing a local deployment due to strict security requirements, we can arrange a custom implementation at an agreed fee.

.png?width=350&height=147&name=Imerso_Logo_A4_White_Transp%201%20(1).png)