Table of Contents

The Need For AI on Construction Sites For Site Monitoring

Bridging BIM Plans and the Construction Site Reality

NHN Implements Imerso and Sets Expectations

Using Imerso for Construction Site Monitoring: Unprecedented Efficiency

Cost Reduction Through Prevented Rework

Accurate As-Built Documentation at Every Stage of The Project

The Need For AI on Construction Sites For Site Monitoring

The construction sector is notorious for ists lagging rates of work productivity and a deep reliance on outdated and inefficient practices.

As one of the world’s least digitised sectors, there is growing pressure for a modernisation of the construction industry – and leading players are taking notice, already exploring novel ways of working through digital workflows. Here are 7 Powerful Ways of Using Imerso to Supercharge Your Construction Projects.

Keeping As-Built Documentation Up-to-Date

One of the major challenges in every construction project is the lack of accurate and current documentation of what has actually been built so far (As-Built documentation). In addition, this must be paired with a systematic way of tracking work quality and progress, able to efficiently identify and resolve issues on a frequent routine.

Existing Control Methods Can't Keep Up With Site Progress

For years, the industry standard for quality control and progress tracking remains on using manual spot-check inspections with checklists and photos – slow, inaccurate and subjective, while only covering a small portion of the total work.

“Site supervision is mostly based on trade-specific topics with a narrow focus on predefined sample areas, traditionally based on printed drawings and tape ruler measurements.”- says NHN Project Leader Anders Kaas.- On a large hospital project like ours, this task is very time consuming, with the high risk of critical items possibly being overlooked.”

The Nyt Hospital Nordsjælland construction is planned to complete in 2026.

Without proper documentation and quality tracking, it can be extremely difficult to ensure that the construction follows the intended specifications and compliance measures.

This typically leads to major challenges in keeping multiple teams coordinated and on the same page, while leaving problematic deviations undetected until it's too late.

Consequences of Insufficient Control Mechanisms

Usually, the longer the above challenges exist, the more costly mistakes and delays occur. Besides the costs, other common negative consequences are: resource waste, partner disputes, and safety hazards, which negative impact on the project escalates rapidly.

The Capital Region of Denmark, which owns the NHN project and is responsible for project management, made a thorough market research and has turned to the Norwegian tech startup Imerso to help resolve these challenges.

Bridging BIM Plans and the Construction Site Reality

Imerso works in three steps to monitor the As-Built reality against the planned construction specifications.

Step 1: Upload the BIM Models

The first step is to upload the project BIM building plans, which serve as the performance targets that Imerso uses to check if everything is on track.

Step 2: Capture the As-Built of the Construction Site

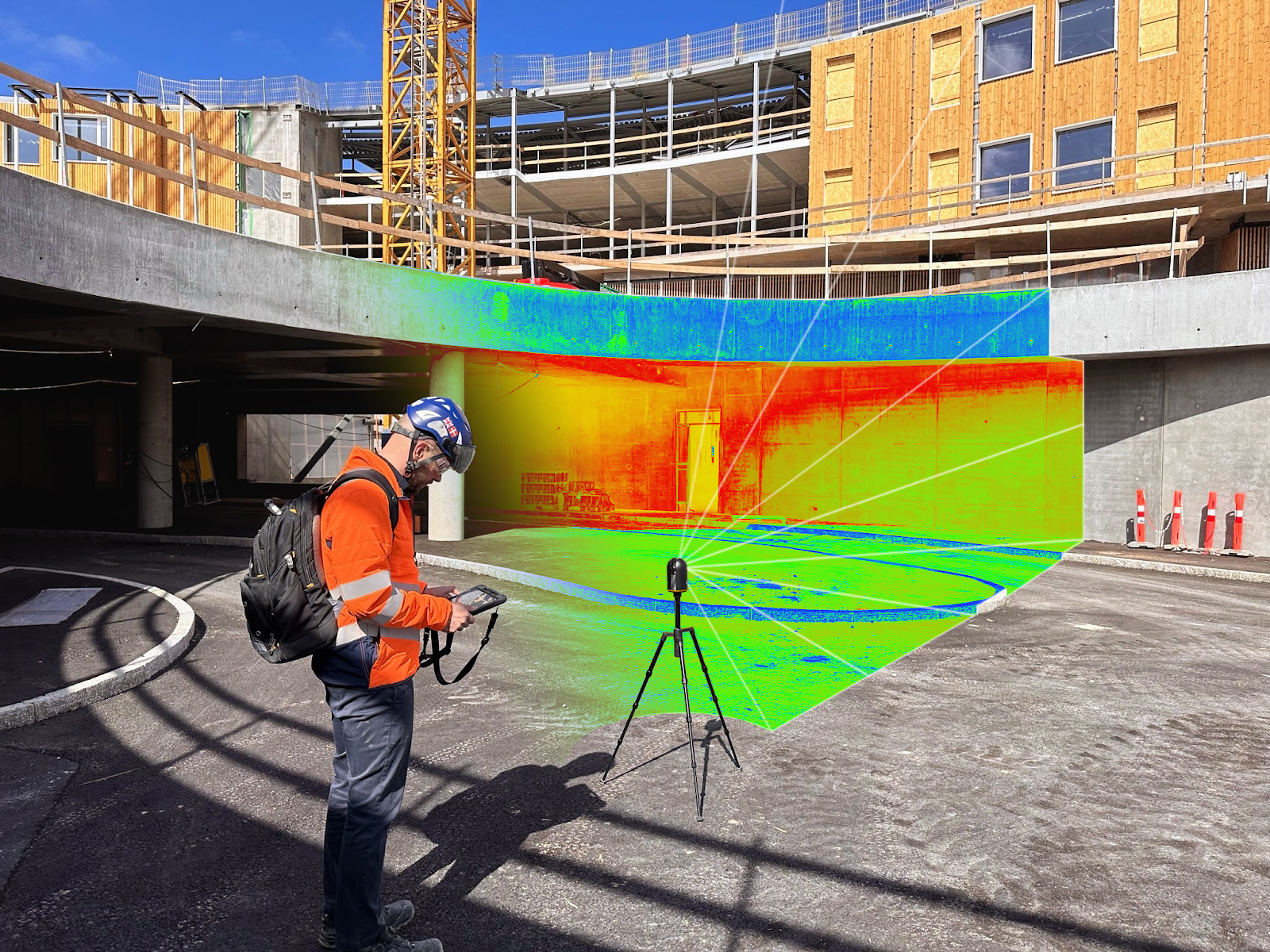

The second step is to capture the As-Built reality using Imerso’s 3D simple scanning process. It enables onsite teams to frequently capture the site status, fast and with millimeter precision. There is no need for advanced training, or any complicated processes, including preparing the area with target markers. Just point and shoot.

“Using Imerso to apply 3D scanning as a fast and less-biased method, both efficiency and the number of construction elements covered increased significantly”, says Anders.

Anders scanning the construction jobsite. Imerso makes 3D scanning easy, so anyone onsite can do it frequently.

Anders scanning the construction jobsite. Imerso makes 3D scanning easy, so anyone onsite can do it frequently.

Step 3: Inspect the Construction Site Automatically

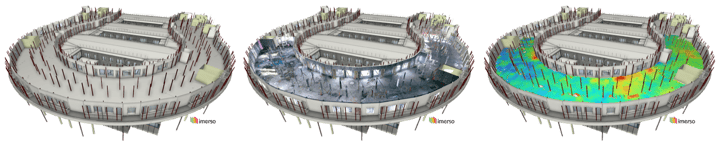

The third step is to review the automatic inspection results in Imerso

- reports of the verified completed work, alongside

- early alerts of deviations and their details

Combining AI with 3D scanning and BIM, Imerso makes the entire process seamless and automated since the beginning, with results delivered within minutes or hours. Then, all the data can be shared with responsible teams in an online collaboration environment.

Checking compliance by comparing building plans with the construction site reality.

Checking compliance by comparing building plans with the construction site reality.

- Frequent and accurate As-Built documentation of every construction stage across the entire site

- Quality control of the jobsite early issue detection

- Verification of completed works, current site status and progress supervision.

Learn about AF Gruppen's Secret Workflow For Lean Quality Control in Construction >>.

NHN Implements Imerso and Sets Expectations

In October 2021, the Capital Region of Denmark purchased a 3D laser scanner to use with Imerso. The initial business case expected a target cost-savings of 4x times the total price of the software and scanning equipment used during the project.

These savings were expected to stem from three main target areas:

- a reduction in construction claims for work errors,

- faster and better site supervision efforts, and

- more efficient process for As-Built documentation.

The construction team implemented the routine in several processes and was able to rapidly demonstrate the value of this new source of data – and the requests for more scanning kept growing.

According to Anders, “The fact that Imerso enables any of us to 3D scan an area in the morning and after lunch, have a full analysis available to review, is really improving the way we approach quality or interface issues. Using 3D scanning on a daily basis like this was not possible before”.

Using Imerso for Construction Site Monitoring: Unprecedented Efficiency

One immediate improvement was seen in a higher efficiency to monitor the site status. The process to inspect numerous elements onsite, document any deviation accurately and make this information available to other project members drastically shortened.

More in 65 days, than an entire teamcould do in one year. |

By comparing the speed of the new approach to traditional methods, it was found that Imerso’s method is over 15 times more efficient at monitoring the site status. Imerso uses less than 10% of the resources required by the traditional methods and delivers much higher quality information.

It would take an entire team more than a year using traditional inspection methods to achieve the same number of verifications of onsite installations that Anders and a couple of interns achieved in 65 days.

“Besides the measurable benefits from a risk perspective, we see that having a broad view on quality assurance also has a positive effect on the amount of rework, and therefore creating a more motivating working environment”, says Anders.

Read more customer cases of Imerso on construction sites>>

Over 5 Mn EUR saved from avoided rework and increased worker productivity. |

Cost Reduction Through Prevented Rework

After 16 months, Imerso had already prevented 440 issues of mixed severity, through their early detection, giving the project teams full context and details for a swift resolution before the problems escalate.

Construction site Detection: Missing opening for large HVAC components

Construction site Detection: Missing opening for large HVAC components

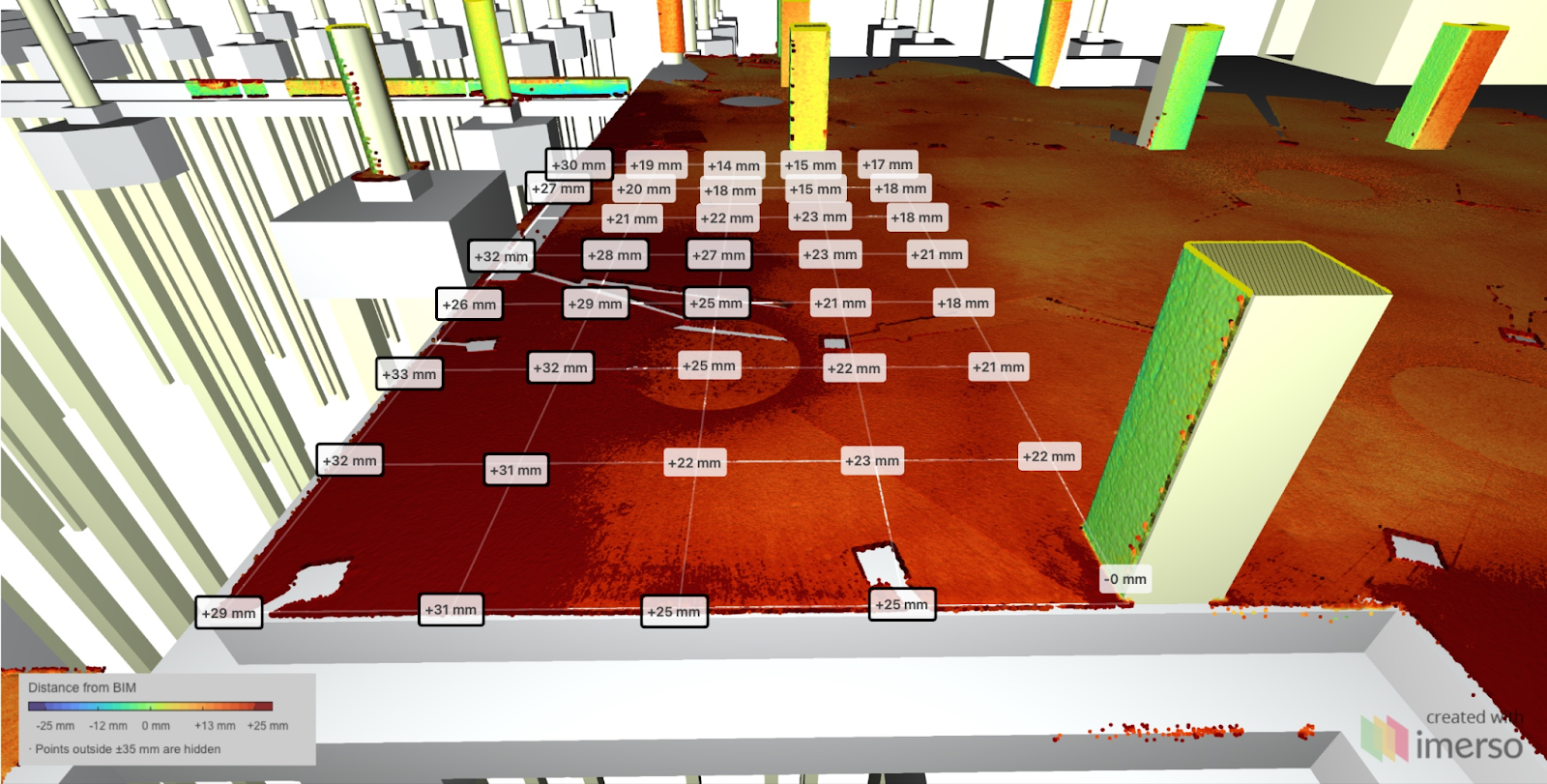

Cost savings per detection range wildly depending on the type of error, the disciplines involved, and the detection timing.

Detection: Edge of floor slab elevated out-of-tolerance

From analysing a wide sample of cases, the NHN team estimates a conservative cost-saving average of €14.000 per avoided issue (industry studies place this between €14.000 and €17.500).

“Instead of using the tool as a punishment tool for the contractor, we’ve set up a collaborative organisation with the contractors and consultants, where possible issues are discussed and further qualified in the site office, - says Anders. - This is done in a controlled environment, several months before the issue potentially results in a negative impact on-site, often affecting budget or time schedule.”

Detection: Steel column installed on-site with a 90º rotation

In little over one year of using Imerso, and with still years to reach project completion, the NHN team estimates savings over € 5.2 million, equivalent to 2% of the total construction budget. These are costs that the project would have incurred in the form of construction rework, delays, waste, and lower worker productivity from using traditional methods.

53 times faster and more accurate than traditional documentation methods, at less than 2% of the resources. |

Accurate As-Built Documentation at Every Stage of The Project

By making 3D scanning as simple as taking a photo, the platform enables the NHN teams to capture every stage of the project with high-accuracy data, without the need for complicated workflows or costly third-party services.

NHN estimates that Imerso’s approach is 53 times faster at creating As-Built documentation, with orders of magnitude in better detail and quality, using less than 2% of the resources that traditional approaches need.

With more recent scanners like the new BLK360 G2 scanner from Leica Geosystems – the documentation speed will further improve by 5x.

Conclusion

“Deciding to implement Imerso’s 3D scanning process during the ongoing construction phase, did challenge the traditional way of working and brought initial skepticism. But after seeing the results and benefits, we now get weekly requests from all parties for new areas to explore with the technology.

On future projects, we have the opportunity to integrate technology like Imerso in the planning and contractual phase of the project, so even more value can be achieved.” - says Anders.

According to Frederico Valente, CEO and Founder of Imerso, “The way construction projects are managed today suffers hugely from a lack of updated and objective information about what’s actually happening out there in the jobsite.We see a growing investment into better planning methods like BIM, but little into mechanisms to ensure those plans are actually carried out in reality.

We’re hugely proud of our collaboration with NHN and the results Anders and his team are achieving in this project, and their dedication to continuous improvement”.

About Imerso

Imerso is a software platform that combines BIM, Reality Capture, and AI technologies to automate construction site supervision and quality inspections with one simple workflow. We help construction companies cut project risks and delay costs with real-time monitoring of site status and work quality. Learn more here>>.

Title photo credit: DronePixels.dk

.png?width=350&height=147&name=Imerso_Logo_A4_White_Transp%201%20(1).png)